Research

Simulations

One of the Basque Center for Applied Mathematics’ goal is to enable effective modelling and detailed simulations of extremely large, complex systems and phenomena, which are not possible with existing simulation methods and often without High Performance Computers (HPC). Below you can see some featured simulations created by the different research groups at the center. You can also visit our Youtube channel to see more simulations.

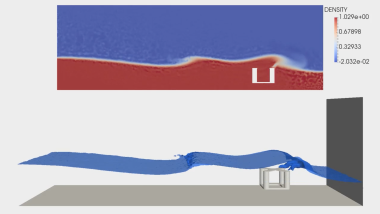

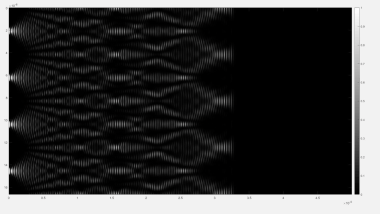

Simulation of a wild-fire front trespassing a short firebreak

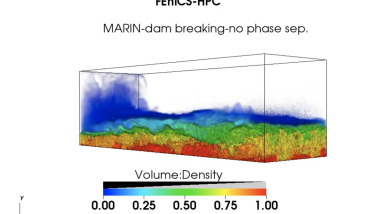

The MARIN benchmark (without phase separation)

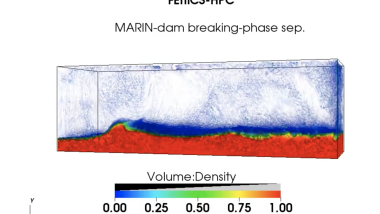

The MARIN benchmark (with phase separation)

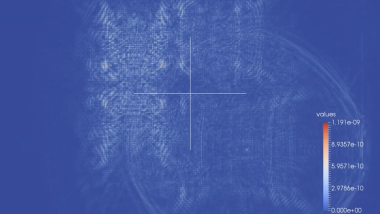

Patient-specific simulation of Cortical Spreading Depression

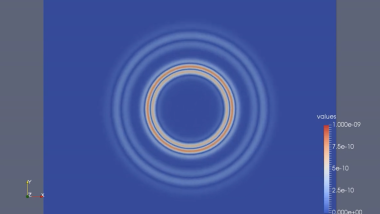

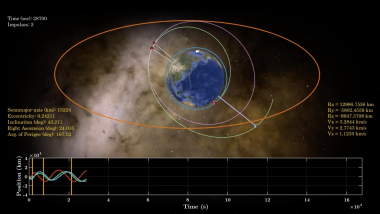

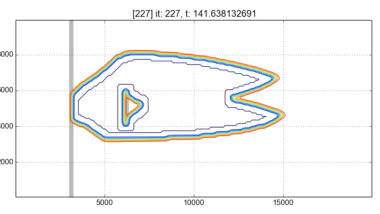

Evolution of a circular vortex: an experiment

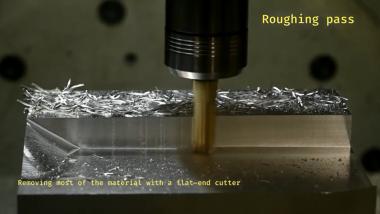

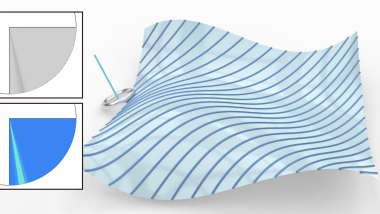

Tool-wear optimized motion planning for 5-axis CNC machining of free-form surfaces

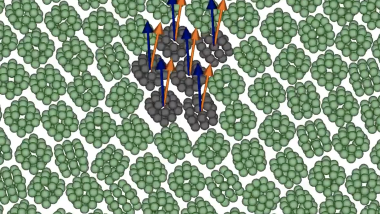

In this video, we showcase results from our paper [1] on motion planning for 5-axis CNC machining of free-form surfaces using a toroidal cutting tool. Starting from a reference surface and contact paths, our framework optimizes the motion of the tool by minimizing the machining error and distributing the tool wear as uniformly as possible along the cutting edge, while remaining locally and globally collision-free. The visualization highlights how the tool wear accumulates during machining: the wedges of the tool’s meridian circle are color-coded by usage, with no wear (light) up to maximum wear (dark). [1] Kruppa, K., Zaragoza Chichell, J., Bizzarri, M., Bartoň, M. “On Tool Wear Optimized Motion Planning for 5-Axis CNC Machining of Free-Form Surfaces Using Toroidal Cutting Tools.” Computer-Aided Design 189 (2025): 103952. https://doi.org/10.1016/j.cad.2025.10....